Coarse grinding and fine grinding of rubber rollers

Release time:

2019-04-04

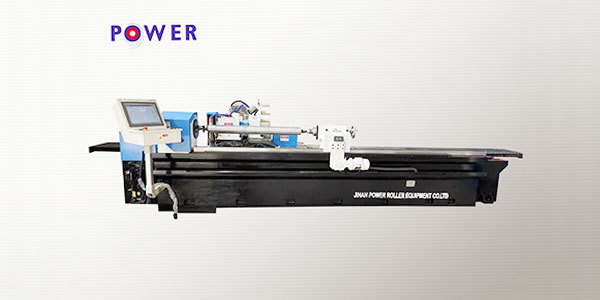

The grinding of the rubber roller is through the accurate and stable relative movement of the grinding wheel and the rubber roller, and the surface of the rubber roller is ground by the particle blade of the grinding wheel, and the quality and stability of the grinding machine and grinding wheel directly affect the grinding quality of the rubber roller surface.

The grinding of the rubber roller is through the accurate and stable relative movement of the grinding wheel and the rubber roller, and the surface of the rubber roller is ground by the particle blade of the grinding wheel, and the quality and stability of the grinding machine and grinding wheel directly affect the grinding quality of the rubber roller surface. Usually choose a green silicon carbide or silicon carbide grinding wheel with a particle size of 40-80 atmospheric hole, and choose a grinding wheel with medium and low hardness, too hard abrasive particles can not fall off smoothly after dullness, grinding force and heat increase affect the surface quality of the rubber roller after grinding. The grinding wheel must be balanced and trimmed before use, and the two edges of the grinding wheel should be chamfered by old grinding wheels or oil stones.

1. Coarse grinding

Coarse grinding rubber roller can choose the particle size of 40, 46, 54, width of 30mm atmospheric hole grinding wheel, the total grinding volume is generally 1mm, can be divided into three passes, the feed amount can be 0.4mm, 0.3mm, 0.3mm, respectively, which is conducive to reducing the surface temperature of the rubber roller. Since coarse grinding has no strict requirements for the surface roughness of the rubber roller, it is mainly to ensure the cylindricality of the rubber roller surface. Fine grinding should not be carried out immediately after coarse grinding, and the parallel rubber roller should be placed for 48h to allow it to be carried out after aging treatment.

2. Fine grinding

Fine grinding rubber roller can choose the particle size of 60, 70, 80, width of 30mm atmospheric hole grinding wheel, the total grinding volume is generally 0.5mm, cotton spinning enterprises generally only need to regrind without coarse grinding, the total amount of grinding is generally 0.3mm-0.4mm, can be divided into three times, the feed volume can be 0.2mm, 0.1mm, 0.1mm, the use of small load grinding can make the surface heat of the rubber roller be controlled, grinding dust is also less, more conducive to the cleaning and sharpness of the grinding wheel. Under the premise of the safety line speed of the grinding wheel, in order to ensure the grinding quality, the general grinding wheel spindle speed is 1800r/min, and the corresponding head speed is about 200r/min. Before grinding, it is necessary to adjust the tail seat of the grinding machine to ensure that the taper of both ends of the rubber roller after grinding is not more than 0.03mm, the grinding stroke should be set to automatic passing to ensure uniform grinding speed, and the last pass speed should be slow, 3m/min-4m/min. After fine grinding, the rubber roller rubber layer should be fine and smooth, and there is no helix on the surface of the surface, no mechanical corrugation, and the surface roughness Rat reaches 0.4μm-0.6μm.

RELATED INFORMATION