Improvement of traditional rubber roller production process

Release time:

2019-01-09

In the rubber products industry, rubber roller is Igor more special products, it is widely used, the technical requirements for rubber materials are different, the use environment is complex, in terms of processing it belongs to thick products, rubber materials can not have pores, impurities and defects. In addition, the products must be joined with the steel shaft, so the bonding of glue to the shaft core is also very important.

In the rubber products industry, rubber roller is Igor more special products, it is widely used, the technical requirements for rubber materials are different, the use environment is complex, in terms of processing it belongs to thick products, rubber materials can not have pores, impurities and defects. In addition, the products must be joined with the steel shaft, so the bonding of glue to the shaft core is also very important.

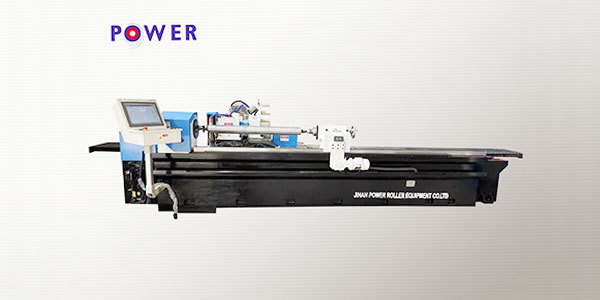

At present, the relatively advanced and mature rubber roller production process is winding type. Our company has developed a set of advanced winding molding equipment. The advanced and advantages of the rubber roller winding molding process are as follows.

1. Reduce labor intensity and improve labor productivity.

The traditional process is to press the compound into sheets on the mill and then coat it on the shaft core. The rubber roller with the specification of Φ80x1000 produces an average of 20 pieces per shift, and the winding process from feeding to rubber roller forming is through continuous temperature adjustment, pressurization and exhaust, and then discharge the dense rubber material under high temperature and high pressure directly wound and form on the required workpiece, the whole process only needs 2 people to operate the computer to complete, 3 people to produce the same specifications of the rubber roller as above can complete 70-90 pieces per shift.

2. Reduce material consumption and reduce production process

The traditional production process: the rubber roller before vulcanization needs to be tightly tied with water, and the rubber material Shore A type needs to be wrapped with iron wire when the hardness is above 80 degrees. The use of winding process can reduce this part of the cost and labor, and this alone can save more than 100,000 yuan in wire costs per year.

RELATED INFORMATION