Introduction to the molding process of rubber rollers

Release time:

2019-01-08

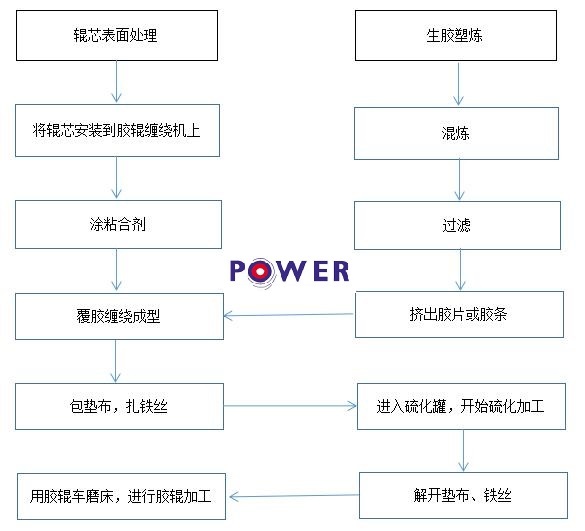

The molding process of rubber rubber roller is similar to other solid rubber products is the preparation of mixed rubber, that is, first use a high-power mill to plasticize some raw rubber, give plastic to the raw rubber, for later molding processing.

The molding process of rubber rubber roller is similar to other solid rubber products is the preparation of mixed rubber, that is, first use a high-power mill to plasticize some raw rubber, give plastic to the raw rubber, for later molding processing. Then the raw rubber or plastic rubber and various compounding agents are put into the mixer for uniform mixing. Because the surface requirements of the rubber roller are very high, no impurities can be mixed into the rubber material, otherwise it will seriously affect its performance, so the rubber must be filtered after mixing.

Then there is tablet pressing and calendering, that is, pressing out a thin and uniform film for use in the next molding process. Forming process is an important part of rubber roller production, its methods are also diverse, the current use of most of the rubber roller rubber covering machine automatic winding coating, Jinan Qiangli rubber roller equipment Co., Ltd. is a professional production and supply of rubber roller rubber covering and other processing equipment.

The formed rubber roller is then wrapped with cloth, tied tightly with iron wire, and sent to the vulcanization tank for vulcanization. After vulcanization, it is also necessary to turn and grind to ensure the finish and dimensional accuracy of the surface of the rubber roller. The following is a compilation of the following rubber roller processing process flow, such as:

The above introduction to the rubber roller forming process is relatively simple, if you want to get more professional knowledge in the production and processing of rubber rollers, welcome to inquire and communicate.

RELATED INFORMATION