PRINTING & PACKAGING ROLLER TECHNIC ROUTE

Release time:

2024-11-15

1、Stripping Machine

The universal type PCM series Stripping Machine is designed to prepare old rubber rollers for the covering process. The tool post accommodates a ring cutting holder removal and allow the abrasive belt sander to remove the last few thousands of materials. Once the surface has been properly prepared you can bond while in the PCM equipment. PCM replace sandblasting processes with environmental pollution. (We do not recommend using)

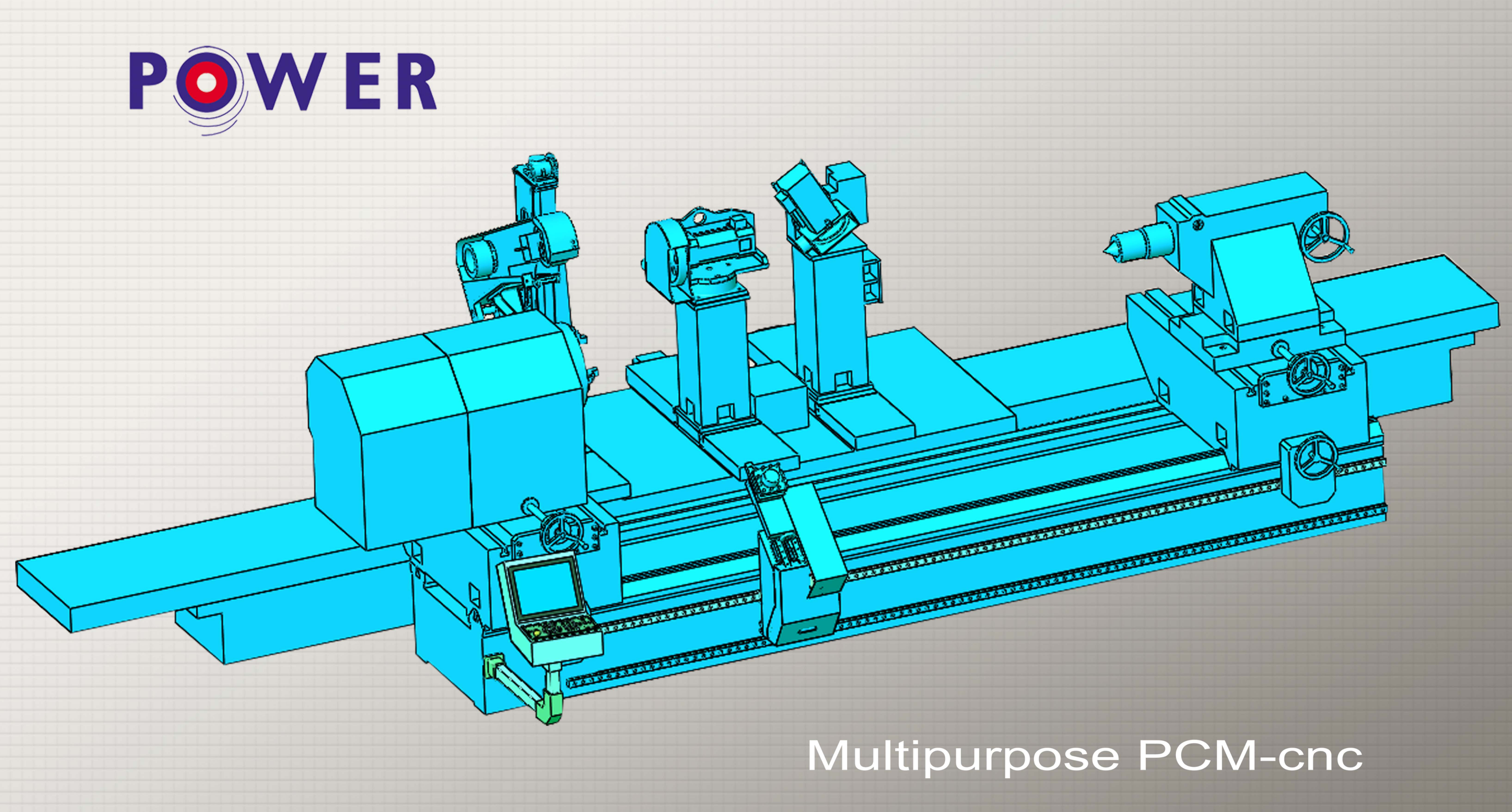

2、Multifunctional PCM-CNC: (we recommend use)

PCM-CNC multifunctional and multi-purpose roller specific grinding machine is an economical integrated grinding machine. It can not only handle old rubber rollers before covering rubber, but also perform rough processing after vulcanization, and can perform various shape grooving processing on the surface of rubber rollers. Reduced the pressure on precision machining equipment, improved production efficiency, and saved production costs.

PURPOSE:

1. Processing of roller cores before vulcanization, removing old rubber, polishing roller cores, and brushing adhesives.

2. Rough machining after vulcanization, equipped with a turning tool to remove the excess after vulcanization;

3. Equipped with specialized alloy grinding wheel for elastomers rough grinding. Rough machining before precision machining is fast because there is no precision requirement for rough machining.

4. Realize grooves of various shapes.

FEATURES:

1. High degree of automation and easy operation.

2. Due to its steel structure bed, it is a very economical and ideal roller processing equipment for meeting rough machining and special requirement

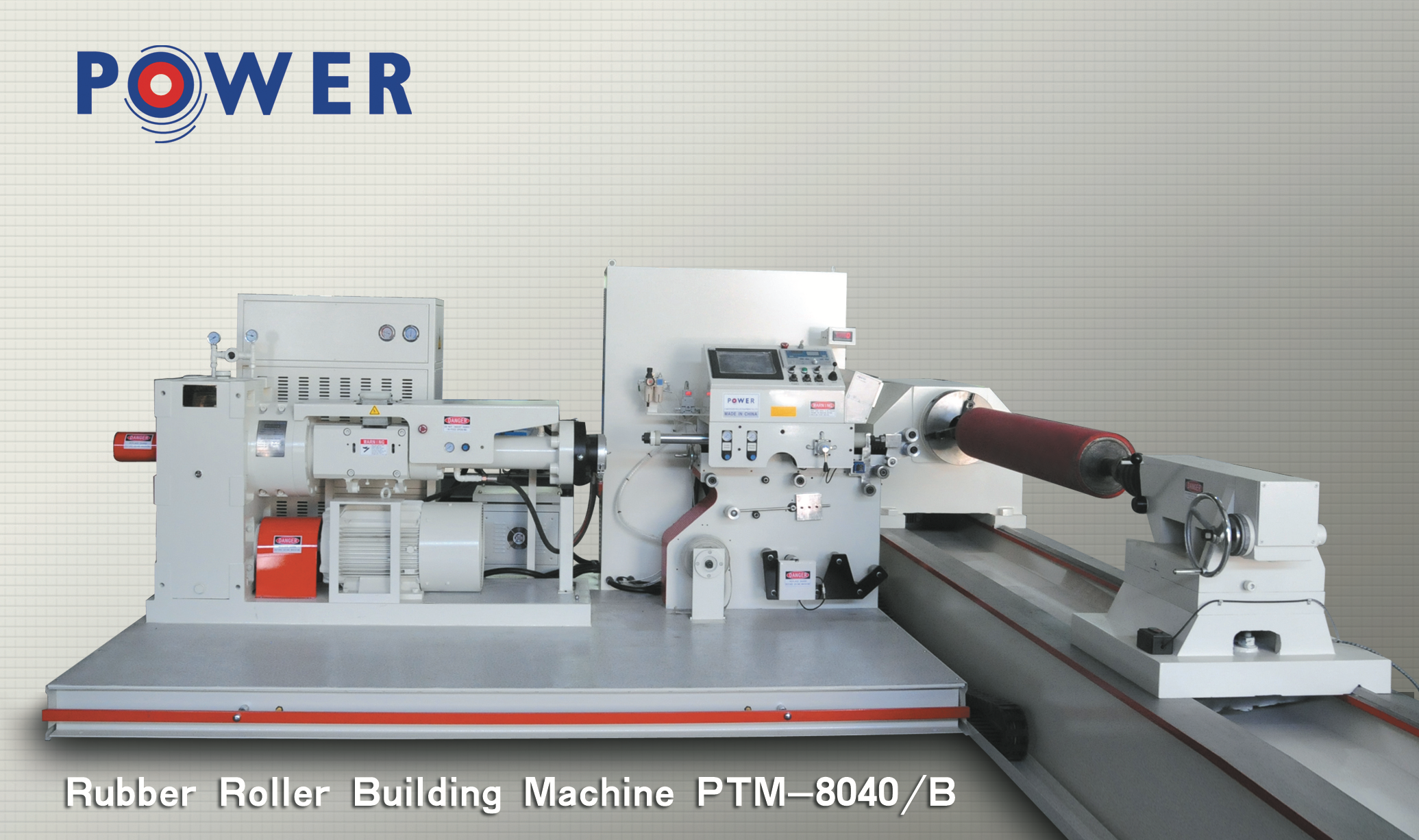

3、PTM-5040 (medium size) Rubber Covering Machine

(Standard/Economic Type)

PTM of medium size is suitable for rubber rollers in the printing, packaging, textile and steel industries. The touch screen operating system fully meets our requirements. The covering form is mainly by flat covering.

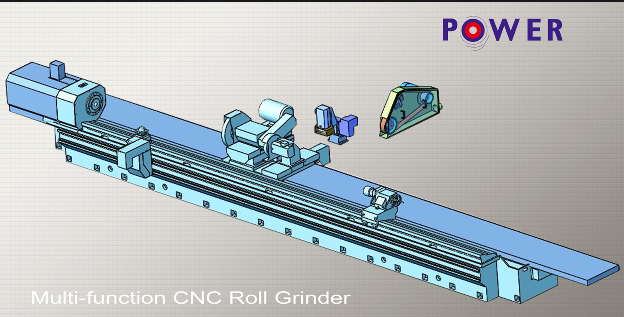

4、MULTI-FUNCTIONAL ROLL GRINDER

Multi-functional medium size rubber roller grinding machine is a preferred equipment for improving production environment and increasing production efficiency. It integrates multiple production processes into one, reducing production links and labor intensity.

The functions of PCG include two medium carriage tables mounted on the movable large carriage table. One equipped with sand wheel grinding head specially designed for printing rubber rollers, another medium carriage table mounted alloy wheel for the other industrial rollers and the polishing device can be interchanged with the alloy grinding wheel device for use. This equipment does not include grooving and cutting tools.

5、Polishing Machine

The PPM series can improve the surface smoothness of rubber rollers. This is achieved by using appropriate sand belt particle size, sand belt pressure, and determined speed. It is very necessary for printing rollers with high surface smoothness requirements.

6、PSF Laser instrument for rollers

In order to operate this project under the principle of low investment cost, it can be invested later.

RELATED INFORMATION