Professional rubber roller equipment manufacturer with research and development innovation

Release time:

2025-01-14

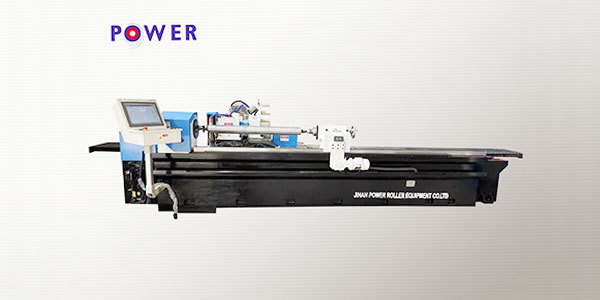

In the ever-evolving manufacturing industry, the need for high-quality machinery is critical. This is especially true in the rubber industry, where precision and efficiency can significantly impact production results. Our company is at the forefront of this innovation and has recently made significant progress in the development of advanced machinery,china high quality long rubber strip feeder, including high-precision CNC multi-hole multi-drilling machines, rubber rolling machines, and high-quality recycled rubber making machines.

The role of R&D in mechanical innovation

Research and development (R&D) plays a vital role in the advancement of manufacturing technology. Our investment in research and development has resulted in the creation of the Multi-Rig, a state-of-the-art piece of equipment designed to meet the specific needs of our customers, roller polishing machine,including a recent order from Spain. This machine is more than just a tool; it represents the result of extensive research, design and testing aimed at improving the efficiency and quality of rubber production.

Multipurpose drill rigs are designed to perform multiple drilling operations simultaneously, significantly reducing production time and increasing throughput. This innovation is a direct result of our technology department’s, china extrusion machine,relentless pursuit of excellence through scientific research and innovation. By continually improving our designs and incorporating customer feedback, we ensure that our machines not only meet industry standards, but exceed them.

High Precision CNC Multi-Hole Multi-Drill Rig: Case Study

High-precision CNC multi-hole multi-drilling rigs are the embodiment of our persistent pursuit of quality and innovation. Developed exclusively for Spanish customers, the machine has undergone a rigorous design adjustment and testing phase. Our team of engineers work tirelessly to ensure every aspect of the machine is optimized for performance.

In June this year, we proudly delivered this cutting-edge equipment to a warm welcome from our customers. Multipurpose drill presses are capable of drilling precise porous patterns into rubber materials, thereby improving product quality and making them a valuable asset in the production of rubber parts. This machine not only streamlines the manufacturing process but also ensures that the final product meets the highest quality standards.

The Importance of Quality in Rubber Manufacturing

In the rubber industry, the quality of machinery directly affects the quality of the final product. Our high-quality recycled rubber making machines are another example of our commitment to excellence. The machine is designed to process recycled rubber efficiently, ensuring that the final product retains its integrity and performance characteristics.

By investing in high-quality machinery, manufacturers can produce rubber products that are durable, reliable, and environmentally friendly. Recycled rubber making machines not only contribute to sustainability by recycling materials, but also improve the overall quality of the rubber produced. In today’s manufacturing environment, a dual focus on quality and sustainability is critical as consumers become increasingly aware of the environmental impact of the products they purchase.

Guarantee quantity without compromising quality

One of the challenges manufacturers face is the need to strike a balance between quantity and quality. Our innovative machinery, including multi-purpose drill rigs and rubber rolling machines, are designed to maximize production efficiency without sacrificing output quality.

For example, a multi-purpose drill press can achieve rapid productivity while maintaining accuracy. This capability is critical for manufacturers who need to meet high demand without compromising product quality. By leveraging advanced technology and innovative design, we help our customers achieve their production goals while ensuring each product meets strict quality standards.

in conclusion

In summary, integrating R&D innovation into the manufacturing process is critical to ensuring quality and quantity of rubber production. Our high-precision CNC multi-hole multi-drilling machines as well as rubber rolling machines and recycled rubber making machines exemplify our commitment to industry excellence.

As we continue to invest in R&D and push the limits of rubber manufacturing, we remain committed to providing our customers with the tools they need to succeed. The successful delivery of a multi-purpose drill rig to our Spanish customer is just one example of how our innovations are shaping the future of the rubber industry. By focusing on quality, efficiency and sustainability, we not only meet the needs of today’s market, roller coating machinery manufacturer,but also pave the way for a more innovative and responsible manufacturing landscape.

RELATED INFORMATION