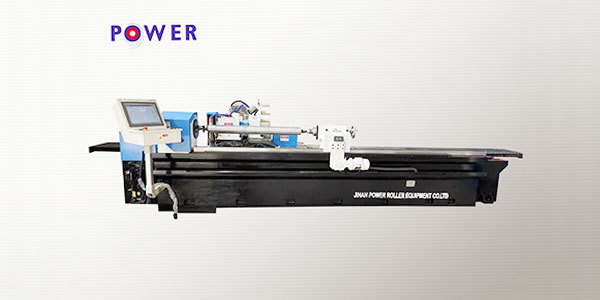

Multifunctional cylindrical grinding machine: a revolution in precision engineering

Release time:

2025-08-08

Multifunctional cylindrical grinding machine: a revolution in precision engineering

The evolution of grinding machines in precision engineering has been nothing short of revolutionary. Among these advancements, multifunctional CNC cylindrical grinding machines stand out as a beacon of innovation, combining cutting-edge technology with diverse applications. This article will delve into the evolution of grinding machines, focusing on multifunctional cylindrical grinding machines and their importance in modern manufacturing.

A Century of Change

Over the past century, the overall structure, operation, function, and purpose of grinding machines have undergone significant changes. The development of grinding machines began with simple casting designs that met basic grinding needs. However, cnc internal grinding machine,as industry evolved and the demand for precision increased, so did the complexity and performance of these machines.

Bed Evolution

The bed structure of grinding machines has undergone significant evolution. Initially, these machines were constructed of simple cast iron, which offered high stability but limited performance. With the emergence of new materials and processes, manufacturers began exploring alloy casting and composite materials. This shift not only improved the durability and strength of the machines but also their overall performance. Modern, versatile cylindrical grinding machines feature a robust bed structure designed to withstand the rigors of high-precision grinding, ensuring consistent results and a long service life.

Advances in operating modes

The operating model of grinding machines has also changed significantly. Early models relied on single-switch controls, which limited their functionality and adaptability. With technological advancements, the introduction of multi-axis control systems equipped with variable frequency drives and servo motors has revolutionized grinding machine operation. Today, multifunctional cylindrical grinders are equipped with intelligent remote control systems that allow operators to monitor and adjust settings in real time.cylindrical grinding machine manufacturers, This level of control not only improves precision but also increases efficiency, making them an indispensable tool in modern manufacturing environments.

Processing functions of multifunctional CNC cylindrical grinder

A major draw of multifunctional cylindrical grinding machines is their extensive machining capabilities. Unlike traditional grinding machines, which are limited to specific tasks, modern CNC cylindrical grinding machines are designed to perform a wide range of operations. This versatility is made possible by advanced programming and automation technologies, enabling the machines to easily execute complex grinding tasks.

App Versatility

This versatile cylindrical grinding machine is capable of processing a wide range of materials, including metals, plastics, and composites. Its adaptability makes it suitable for a wide range of industries, from automotive and aerospace to medical and electronics. Whether grinding shafts, rubber extrusion companies,bearings, or complex components, this machine delivers precision results that meet the stringent demands of modern manufacturing.

Improve accuracy and efficiency

Precision is crucial in any manufacturing process, and this is where the versatile CNC cylindrical grinding machine excels. Leveraging advanced control systems and high-quality components, the machine is capable of achieving tolerances once considered impossible. This precision not only improves product quality but also reduces waste and rework, ultimately saving manufacturers money.

Furthermore, the efficiency of these machines has been enhanced through automation and intelligent programming. Operators can set up complex grinding cycles unattended, freeing up valuable time and resources. This shift toward automation will revolutionize the industry landscape, enabling manufacturers to increase productivity while maintaining high quality standards.

The future of grinding machines

Looking ahead, multifunctional cylindrical grinding machines will play a key role in the continued evolution of grinding machines. With advances in artificial intelligence, machine learning, and the Internet of Things (IoT), cnc cylindrical grinding machine,we can expect even greater levels of automation and connectivity. These technologies will enable real-time monitoring and predictive maintenance, further improving the efficiency and reliability of grinding operations.

in conclusion

In short, the Multifunction CNC Cylindrical Grinding Machine represents the pinnacle of grinding machine technology. Its evolution from a simple casting to a sophisticated, intelligent machine reflects the broader transformation of manufacturing processes over the past century. With its enhanced bed, advanced operating modes, and extensive machining capabilities, this grinder is more than just a tool; it is a vital asset in the modern manufacturing industry's pursuit of precision and efficiency. As standards continue to rise across industries, the Multifunction Cylindrical Grinding Machine will undoubtedly continue to lead innovation and shape the future of precision engineering.

RELATED INFORMATION