PAPER MAKING ROLLER PROCESSING TECHINC ROUTE

Release time:

2024-11-20

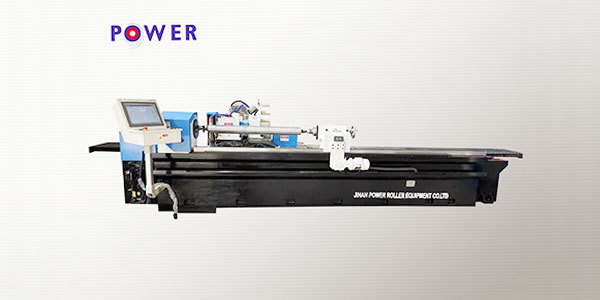

1、Stripping Machine

The universal type PCM series Stripping Machine is designed to prepare old rubber rollers for the covering process. The tool post accommodates a ring cutting holder removal and allow the abrasive belt sander to remove the last few thousands of materials. Once the surface has been properly prepared you can bond while in the PCM equipment. PCM replace sandblasting processes with environmental pollution. (We do not recommend using)

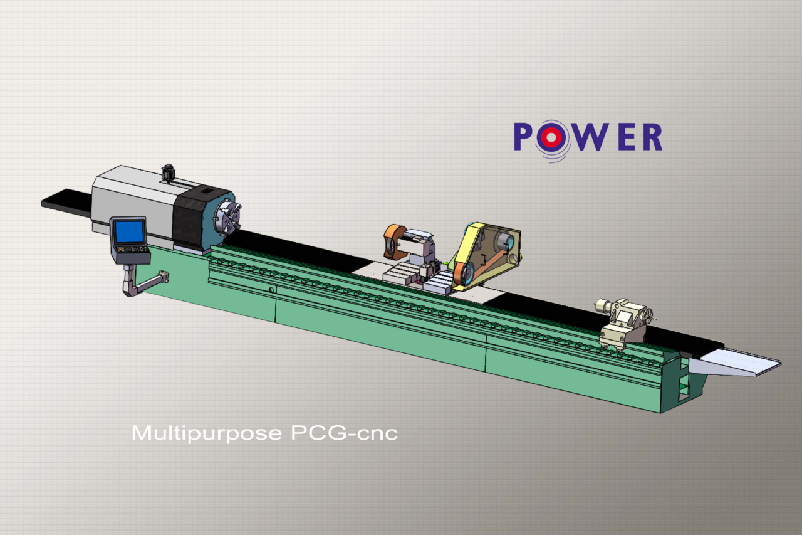

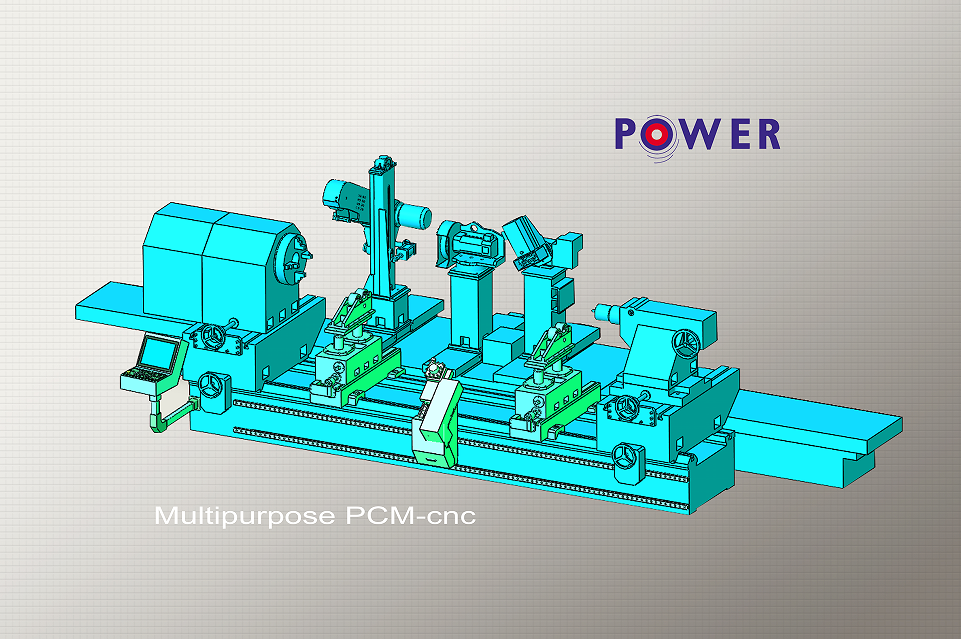

2、Multifunctional PCM-CNC: (we recommend use)

PCM-CNC multifunctional and multi-purpose roller specific grinding machine is an economical integrated grinding machine. It can not only handle old rubber rollers before covering rubber, but also perform rough processing after vulcanization, and can perform various shape grooving processing on the surface of rubber rollers. Reduced the pressure on precision machining equipment, improved production efficiency, and saved production costs.

PURPOSE:

1. Processing of roller cores before vulcanization, removing old rubber, polishing roller cores, and brushing adhesives.

2. Rough machining after vulcanization, equipped with a turning tool to remove the excess after vulcanization;

3. Equipped with specialized metal grinding wheel for elastomers rough grinding. Rough machining before precision machining is fast because there is no precision requirement for rough machining. it is especially suitable for grinding large size rubber rollers that do not meet high precision requirements.

4. Realize grooves of various shapes.

FEATURES:

1. High degree of automation and easy operation.

2. Due to its steel structure bed, it is a very economical and ideal roller processing equipment for meeting rough machining and special requirements

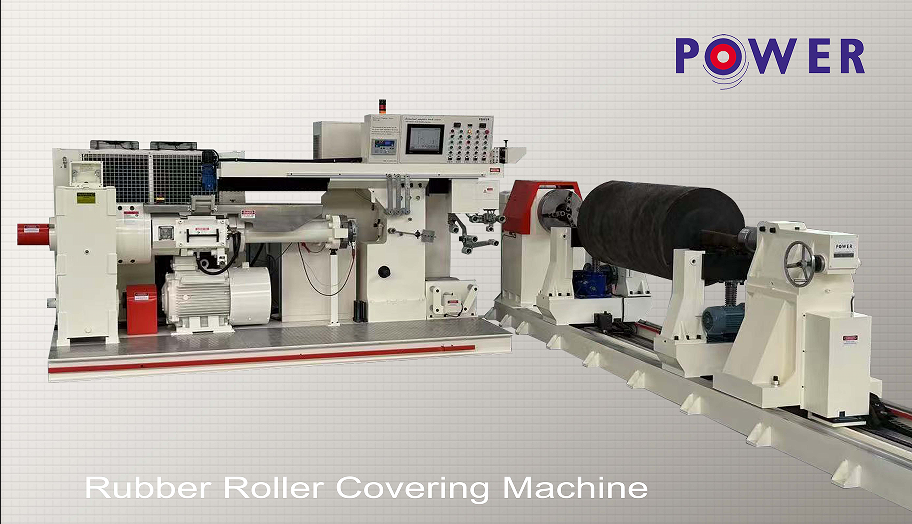

4、PTM-1560 (Big size) Rubber Covering Machine (Superior Type)

These modes are suitable for large rubber rollers such as paper rollers, mining rollers, etc. they have two styles of operation manual and automatic. In the automatic style the ideal covering can be simply completed. The form of the rubber covering includes: flat covering、angle covering and end covering which can be selected by the user.

5.MLTI-FUNCTIONAL ROLL GRINDER

Multi-functional medium size rubber roller grinding machine is a preferred equipment for improving production environment and increasing production efficiency. It integrates multiple production processes into one, reducing production links and labor intensity.

The functions of PCG include grinding the roller surface and performing various shapes of grooving on the roller surface. PCG is an ideal equipment for processing in the rubber roller industry.

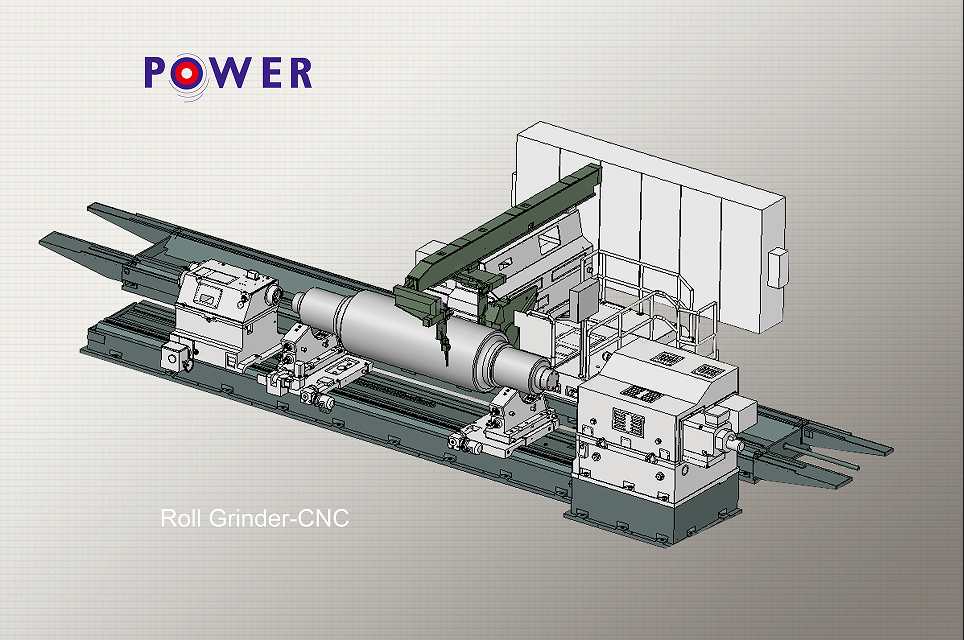

六、PRG CNC Roll Grinder

The PRG series CNC roller grinder is a large-scale roller processing equipment specially customized for different industries, purposes, and specifications

Composition: bed frame, spindle head, grinding wheel rack, tailstock, hydraulic station, electrical cabinet, control system operation panel, etc.

Function: Metal roller, rubber elastic roller flat grinding, multifunctional curve grinding, roller surface grooving, roller surface polishing processing.

- The traditional PRG-CNC/G Roll Grinder adopts cast iron as the bed structure material, which accounts for 80% of the total equipment weight. Due to the characteristics of the material, the equipment has high requirements for environmental temperature, poor seismic performance, and high annual maintenance costs.

- The new-type PRG-CNC/M rock-based CNC Roll Grinder uses a composite stone casting material for the bed structure, which solves the cost of equipment that needs to overcome the environment to maintain accuracy. Due to the characteristics of the material, the equipment has low requirements for environmental temperature, good shock absorption performance, and does not require a large foundation. The annual maintenance cost is low.

- What I want to tell you here is that when we choosing a roller grinder, we must calculate the future operating costs, including foundation, environmental temperature, annual maintenance frequency, etc. These are all hidden costs that will be incurred in the future. China has been producing rock-based composite materials for several years, especially in large-scale processing equipment, which has been recognized by European countries. We suggest that we would considering using this type of composite material.

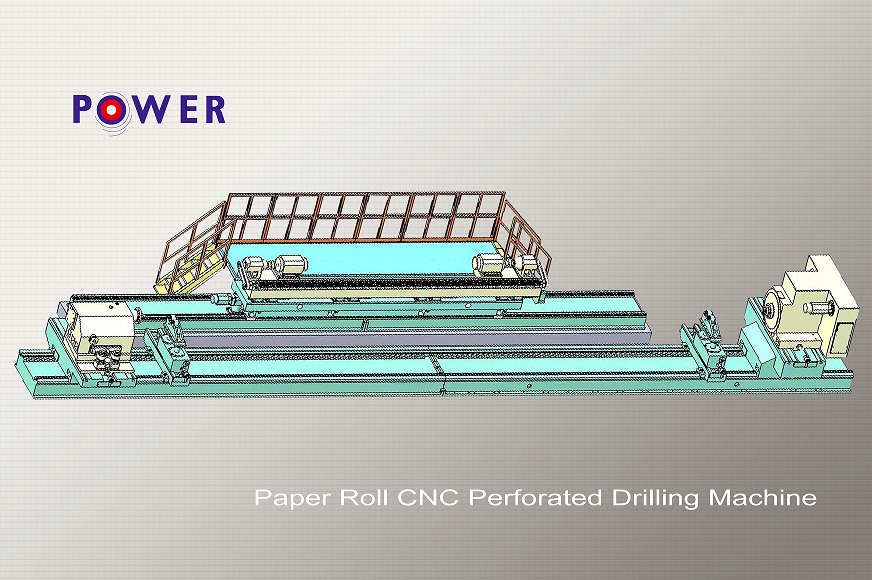

PDM-CNC Porous Drilling Machine

Porous drilling machine is a specialized equipment for drilling holes on paper squeezing rollers. The porous drilling machine produced by POWER has a reasonable mechanical structure and high processing accuracy. In terms of operation, it is currently the most advanced operating mode among porous drilling equipment. Operators do not need any calculations, only need to input processing parameters, The system will automatically generate processing programs, which are easy to learn and operate.

RELATED INFORMATION