The Essential Role of Rubber Roller Machines in Modern Manufacturing

Release time:

2024-11-08

The Essential Role of Rubber Roller Machines in Modern Manufacturing

In the world of manufacturing, precision and efficiency are paramount. One of the unsung heroes of this industry is the rubber roller machine. These machines play a crucial role in the production and maintenance of rubber rollers, which are essential components in various applications, from printing to packaging. This article delves into the significance of rubber roller machines, their types, and their impact on manufacturing processes.

Understanding Rubber Rollers

Rubber rollers are cylindrical components made from rubber or rubber-like materials. They are used in a variety of industries,rubber roller surface grinding machine, including printing, textiles, and food processing. The primary function of rubber rollers is to transfer materials, apply pressure, or provide traction in various processes. Their versatility and durability make them indispensable in many manufacturing settings.

The Rubber Roller Machine: A Comprehensive Overview

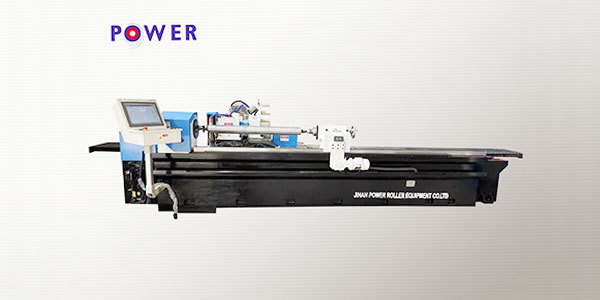

A rubber roller machine is designed specifically for the production, covering, styrene butadiene rubber manufacturers,and maintenance of rubber rollers. These machines come in various forms, each tailored to specific tasks within the rubber roller manufacturing process. The main types of rubber roller machines include:

1. **Rubber Roller Covering Machines**: These machines are used to apply a layer of rubber to a core, which can be made of metal or other materials. The covering process is critical as it determines the roller's performance and longevity. The machine ensures that the rubber is evenly applied, providing a smooth surface that is essential for optimal functionality.

2. **Rubber Roller Grinding Machines**: After the rubber has been applied, it often requires grinding to achieve the desired dimensions and surface finish. Rubber roller grinding machines are equipped with precision grinding tools that can shape and smooth the rubber surface, ensuring that it meets the specific requirements of the application it will be used for.

3. **Rubber Roller Testing Machines**: Quality control is vital in manufacturing, and rubber roller testing machines are used to assess the performance and durability of rubber rollers. These machines simulate the conditions under which the rollers will operate, allowing manufacturers to identify any potential issues before the rollers are put into service.

The Importance of Rubber Roller Machines in Manufacturing

The integration of rubber roller machines into manufacturing processes has revolutionized the way rubber rollers are produced and maintained. Here are some key benefits of using these machines:

1. Enhanced Precision

Rubber roller machines are designed to operate with high precision. This precision is crucial in industries where even the slightest deviation can lead to significant issues, such as misalignment in printing or uneven pressure in packaging. By utilizing advanced technology, these machines ensure that each roller is manufactured to exact specifications.

2. Increased Efficiency

The automation of rubber roller production through specialized machines significantly increases efficiency. Traditional methods of roller covering and grinding can be time-consuming and labor-intensive. Rubber roller machines streamline these processes, allowing manufacturers to produce more rollers in less time, ultimately leading to higher productivity.

3. Improved Quality Control

With the use of rubber roller testing machines, manufacturers can maintain strict quality control over their products. These machines allow for thorough testing of each roller, ensuring that they meet industry standards and customer expectations. This focus on quality helps to reduce waste and minimize the risk of product failure in the field.

4. Cost-Effectiveness

While the initial investment in rubber roller machines may be substantial, the long-term savings they provide can be significant. By increasing production efficiency, reducing waste, and improving product quality, manufacturers can lower their overall operational costs. Additionally, the durability of rubber rollers produced by these machines often leads to longer service life, further enhancing cost-effectiveness.

5. Versatility

Rubber roller machines can be adapted to produce rollers of various sizes and specifications, making them suitable for a wide range of applications. This versatility allows manufacturers to cater to diverse industries, from automotive to food processing, rubber extrusion machine,cnc surface grinder manufacturer,without the need for multiple machines.

Conclusion

In conclusion, rubber roller machines are a vital component of modern manufacturing processes. Their ability to produce high-quality rubber rollers efficiently and precisely has transformed industries that rely on these essential components. As technology continues to advance, we can expect further innovations in rubber roller machines, leading to even greater efficiencies and capabilities in the manufacturing sector. For businesses looking to enhance their production processes, investing in rubber roller machines is a step towards achieving operational excellence and maintaining a competitive edge in the market.

RELATED INFORMATION