Application of The CNC cylindrical grinding machine

Release time:

2024-11-13

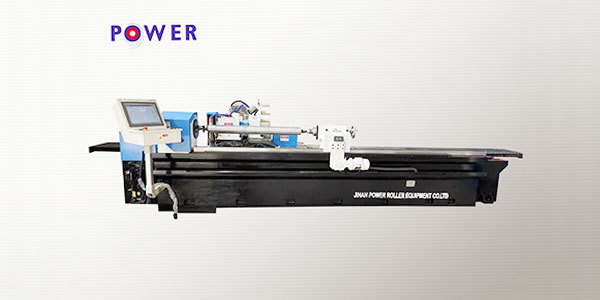

The CNC cylindrical grinding machine is specially designed and manufactured for the fine machining of metal roller core and rubber roller. It can not only flat-grind the workpiece, but also grind the convex and concave surfaces according to the parabolic trajectory. It is the best finishing grinder especially for the printing water roller with stringent requirements.

In the ever-evolving landscape of manufacturing, precision and efficiency are paramount. This is particularly true in industries that rely heavily on rubber components, such as printing, packaging, and automotive sectors. One of the most critical machines in this domain is the high precision CNC cylindrical grinder, specifically designed for the fine machining of rubber rollers and metal roller cores. This article delves into the application of rubber roller grinding machines, particularly those manufactured in China, and highlights their significance in the roller processing industry.

Understanding Rubber Roller Grinding Machines

Rubber roller grinding machines are specialized equipment designed to achieve high precision in the grinding of rubber rollers. These machines utilize advanced CNC (Computer Numerical Control) technology, which allows for automated and highly accurate machining processes. The CNC cylindrical grinding machine is particularly noteworthy for its ability to perform various grinding operations, including flat grinding, convex and concave surface grinding, and parabolic trajectory grinding.

The versatility of these machines makes them ideal for producing rubber rollers that meet stringent industry standards, especially in applications such as printing. For instance, the printing water roller requires a high degree of precision to ensure consistent ink transfer and quality printing results. The CNC cylindrical grinding machine excels in this regard, providing the necessary finishing touches to achieve optimal performance.

The Role of High Precision CNC Cylindrical Grinders

High precision CNC cylindrical grinders are at the forefront of rubber roller manufacturing. These machines are engineered to deliver exceptional accuracy and surface finish, which are critical factors in the performance of rubber rollers. The grinding process involves removing material from the surface of the roller to achieve the desired diameter, roundness, and surface finish.

One of the standout features of these grinders is their ability to grind complex shapes and profiles. This is particularly beneficial for manufacturers who require custom rubber rollers with specific dimensions and surface characteristics. The CNC technology allows for the programming of intricate grinding paths, ensuring that each roller is produced to exact specifications.

Moreover, the integration of advanced sensors and feedback systems in these machines enhances their operational efficiency. They can monitor the grinding process in real-time, making adjustments as needed to maintain precision and prevent defects. This level of automation not only improves productivity but also reduces the likelihood of human error, resulting in higher quality products.

The Chinese Manufacturing Advantage

China has emerged as a leading manufacturer of rubber processing machinery, including high precision CNC cylindrical grinders. The country’s robust industrial infrastructure, coupled with a focus on technological innovation, has positioned it as a key player in the global market. Chinese manufacturers are known for producing high-quality machines at competitive prices, making them an attractive option for businesses looking to invest in rubber roller grinding technology.

In addition to cost-effectiveness, Chinese manufacturers often offer a wide range of customization options. This flexibility allows companies to tailor machines to their specific needs, whether they require a particular grinding capacity, size, or additional features. As a result, businesses can optimize their production processes and enhance their product offerings.

Applications in Various Industries

The application of rubber roller grinding machines extends across multiple industries. In the printing industry, for example, the quality of rubber rollers directly impacts the final product. High precision grinding ensures that rollers maintain uniform thickness and surface texture, which is essential for achieving consistent print quality.

In the packaging sector, rubber rollers are used in various processes, including laminating, coating, and sealing. The performance of these rollers can significantly affect the efficiency of production lines. By utilizing CNC cylindrical grinders, manufacturers can produce rollers that enhance the speed and reliability of packaging operations.

The automotive industry also benefits from high precision rubber roller grinding machines. Rubber rollers are used in various applications, including conveyor systems and engine components. The ability to produce rollers with precise dimensions and surface finishes contributes to the overall performance and longevity of automotive products.

Conclusion

The application of rubber roller grinding machines, particularly high precision CNC cylindrical grinders, plays a vital role in the manufacturing of rubber components across various industries. With their ability to deliver exceptional accuracy and surface finish, these machines are indispensable for producing high-quality rubber rollers that meet stringent industry standards.

As Chinese manufacturers continue to innovate and expand their offerings, businesses worldwide can leverage the advantages of these advanced machines. By investing in high precision CNC cylindrical grinders, companies can enhance their production capabilities, improve product quality, and ultimately gain a competitive edge in the market. The future of rubber roller manufacturing looks promising, driven by technological advancements and the relentless pursuit of precision.

RELATED INFORMATION