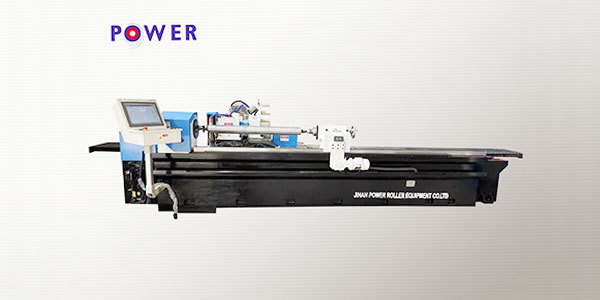

PSM Multifunctional CNC Grinding Machine

Release time:

2024-12-06

Mainly used for turning, grinding, and grooving the surface of rubber elastomers

PSM Multifunctional CNC Grinding Machine: Revolutionizing Rubber Roller Processing

In the ever-evolving landscape of manufacturing, the demand for precision and efficiency has never been higher. The PSM multifunctional CNC grinding machine stands at the forefront of this revolution, particularly in the processing of rubber elastomers. This advanced machinery is not just a grinding tool; it is a comprehensive solution that integrates multiple functionalities, including turning, grinding, and grooving, making it an indispensable asset for industries that rely on rubber roller production.

Understanding the PSM Multifunctional CNC Grinding Machine

The PSM multifunctional CNC grinding machine is engineered to meet the diverse needs of rubber processing. Its primary function is to turn, grind, and groove the surfaces of rubber elastomers, which are critical components in various applications, from automotive to industrial machinery. The machine's versatility allows manufacturers to achieve high precision in shaping and finishing rubber rollers, ensuring that they meet stringent quality standards.

One of the standout features of the PSM machine is its CNC (Computer Numerical Control) technology. This allows for automated control of the machining process, significantly reducing the risk of human error and enhancing production efficiency. Operators can program the machine to perform complex tasks with ease, resulting in consistent quality and reduced cycle times.

The Role of Rubber Roller Grooving Machines

In the realm of rubber processing, the rubber roller grooving machine plays a crucial role. Grooving is essential for creating patterns on rubber rollers that enhance their functionality, such as improving grip or facilitating better fluid transfer. The PSM multifunctional CNC grinding machine incorporates grooving capabilities, allowing manufacturers to produce rollers with precise grooves tailored to specific applications.

The integration of grooving functionality into the PSM machine eliminates the need for separate equipment, streamlining the production process. This multifunctionality not only saves space in the manufacturing facility but also reduces operational costs by minimizing the number of machines required for rubber roller production.

Enhancing Precision with Rubber Roller Measuring Machines

Precision is paramount in the manufacturing of rubber rollers, and the PSM multifunctional CNC grinding machine is designed with this in mind. The machine can be paired with rubber roller measuring machines, which ensure that the dimensions and specifications of the rollers meet the required standards. This combination of grinding and measuring capabilities allows for real-time adjustments during the production process, further enhancing the accuracy of the final product.

By integrating measuring technology, manufacturers can quickly identify any discrepancies in size or shape, allowing for immediate corrections. This not only improves the quality of the rubber rollers but also reduces waste and increases overall efficiency in the production line.

The Advantages of Using the PSM Multifunctional CNC Grinding Machine

1. **Versatility**: The PSM multifunctional CNC grinding machine is capable of performing multiple operations, including turning, grinding, and grooving. This versatility makes it suitable for a wide range of rubber processing applications.

2. **Increased Efficiency**: With CNC technology, the machine operates with high precision and speed, significantly reducing production times. The automation of processes minimizes manual intervention, allowing operators to focus on other critical tasks.

3. **Cost-Effectiveness**: By combining multiple functionalities into a single machine, manufacturers can save on equipment costs and maintenance. The reduction in the number of machines required also leads to lower operational expenses.

4. **Enhanced Quality Control**: The ability to integrate measuring machines with the PSM grinding machine ensures that every rubber roller produced meets the highest quality standards. This commitment to quality is essential in maintaining customer satisfaction and loyalty.

5. **User-Friendly Interface**: The PSM multifunctional CNC grinding machine is designed with an intuitive user interface, making it accessible for operators with varying levels of experience. This ease of use contributes to a smoother production process and reduces training time.

Conclusion

The PSM multifunctional CNC grinding machine is a game-changer in the rubber processing industry. Its ability to turn, grind, and groove rubber elastomers with precision and efficiency sets it apart from traditional machinery. By integrating the functionalities of rubber roller grooving machines and measuring machines, the PSM machine not only enhances production capabilities but also ensures that manufacturers can meet the ever-increasing demands for quality and performance.

As industries continue to evolve, the need for advanced machinery like the PSM multifunctional CNC grinding machine will only grow. Embracing this technology will empower manufacturers to stay competitive in a fast-paced market, ultimately leading to greater innovation and success in the rubber processing sector.

RELATED INFORMATION